01 February 2022 | Climate Tech

H2-zero: decarbonizing hydrogen ⬇️

By

If you keep an eye on our weekly round-up emails on Sundays, you’ll have noticed a bevy of ‘green’ hydrogen deals hit the wire over the past few weeks and months. These are companies whose business and technology centers on producing hydrogen with low-to-no carbon emissions.

For example:

- Last week, H2Pro raised $75M in Series B funding for their ‘E-TAC’ technology. E-TAC = a more efficient way to produce hydrogen from water via electricity.

- Last year, Iberdola and H2 Green Steel partnered to build a $2.6B ‘green’ hydrogen plant in France. This plant alone would represent more installed capacity for the technology it would use than existed in the world in 2020.

Taking a step back… what’s the impetus for this focus on hydrogen?

GREEN HYDROGEN AND INDUSTRY

Producing cleaner hydrogen would help decarbonize two of the bigger climate change challenge areas, out there namely industry and electricity generation / storage. Let’s start with industry, as the majority of hydrogen is used in industrial applications.

Demand for hydrogen has grown threefold since 1975. It’s used for things like treating metals like steel, refining petroleum, and making fertilizer.

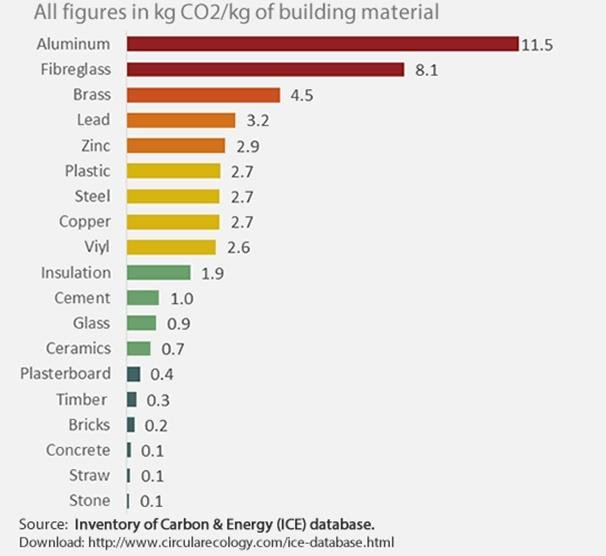

The steel industry is a good case study of an area where hydrogen plays a large role in production and where decarbonizing is a focus. For one, the steel industry is emissions-intensive; steel has a high level of embodied carbon among building materials:

Many large steel companies are feeling the heat and looking for ways to reduce their footprint. For instance? Arcelor-Mittal, one of the largest steel producers in the world, was a notable investor in H2Pro’s Series B round that we mentioned above.

Now, where do the emissions from hydrogen come in?

The production of hydrogen itself adds to the emission of the products it’s used to create. Why? While hydrogen can be isolated from a number of other substances, H2O isn’t the most common choice.

Natural gas is actually the most common input for hydrogen production; 6% of all global natural gas usage goes towards creating hydrogen.

ALTERNATIVE HYDROGEN PRODUCTION METHODS

Many of the new processes and technologies that produce hydrogen sans emissions leverage some version of electrolysis to split hydrogen out of water instead of fossil fuels.

Electrolysis is powered by electricity in a system called an electrolyzer, which isn’t drastically different from a fuel cell. If the electricity used in electrolysis is produced via renewables or nuclear, then the resultant hydrogen production can be close to or entirely carbon-free.

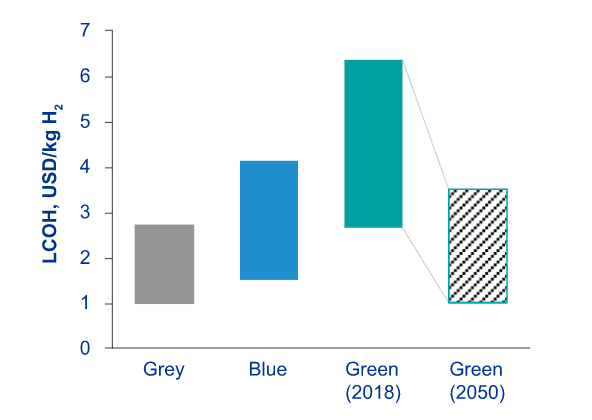

The challenge with this approach? As with other promising climate technologies, it’s more expensive than producing hydrogen from fossil fuels at the moment. Up to 3-4x times as expensive, in fact.

That’s a big gap, and it fuels considerable debate about whether all the money pouring into the space wouldn’t be better spent elsewhere. Can production scale and innovation shift the needle meaningfully here? TBD.

OTHER WILD IDEAS

While you don’t hear as much about hydrogen fuel cell cars anymore, green hydrogen has potential beyond decarbonizing heavy industry. Another opportunity? Producing hydrogen with renewables could also help unblock hydrogen as a form of energy storage:

- The same electrolysis process that converts electricity into hydrogen can be run in reverse.

- During non-peak grid times, excess energy produced by renewables could be converted into hydrogen.

- This hydrogen could then be re-electrified later on, e.g. in hydrogen fuel cells that produce electricity or heat.

The challenge with hydrogen as an energy storage technology is that the roundtrip process described above is less efficient than other energy storage processes. But, the benefit of hydrogen is that it’s easy to store it at scale, especially compared to something like a battery.

That’s another reason why considerable money and time is being spent on green hydrogen: in a future where the grid is electrified, flexible and scalable energy storage options to complement lithium-ion batteries will be important.